Metal seated Zero Leakage High Temperature High Performance Butterfly Valves

Metal Seated High Performance Butterfly Valve

Through years of development, we develop the metal seated high performance butterfly valve with high temperature working range up to 858 ℃. The end connection is available for wafer, full lug, and double flanges type. With advanced technology, the life time more than 100,000 times cycles.

Quick Info:

| Size Range: |

DN50 - DN1500 (2" - 60") |

| Pressure Rating: |

PN16,PN25,PN40 |

| Body Patterns: |

Wafer, Lugged |

| Body Seat: |

316 |

| Body Materials: |

WCB, CF8, CF8M |

| Disc Materials: |

CF8/CF8M |

| Temperature Rating: |

-39°C to +858°C |

| Flange Standards: |

ANSI150, PN6/10/16, JIS 5K/10K/16K/20K |

| Operation: |

Manual, Electric, Pneumatic |

Working principle of metal seat

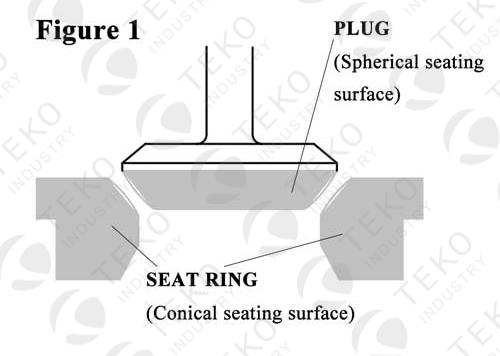

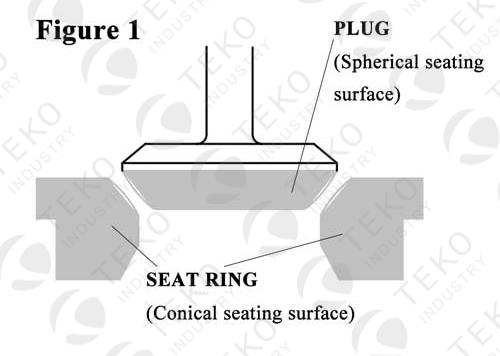

Figure 1 PRINCIPLE OF METAL SEATING

Metal-to-metal sealing is accomplished by the “line contact” between a spherical surface and conical surface. Figure 1 illustrates a typical globe control valve seat and plug. The plug seating surface is the segment of a sphere; when engaged against the seat ring, a line contact seal is achieved.

In a metal seat design, it is necessary to apply enough force per linear inch to maintain a tight metal-to-metal contact between the sealing members; however, high linear thrust can cause a collapse of the seating members (“bearing failure”).

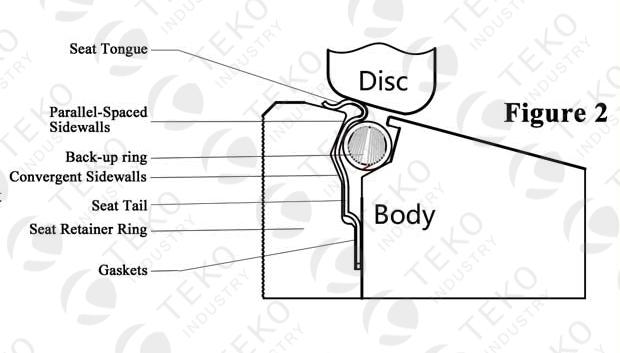

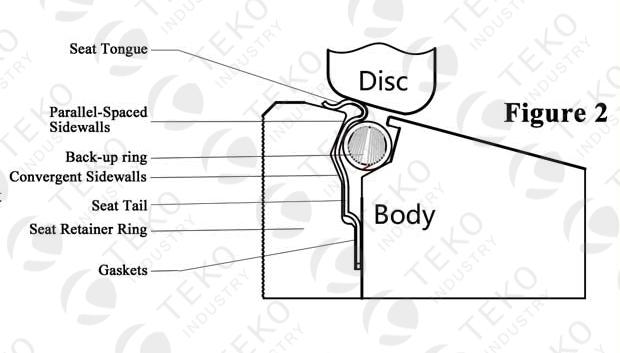

Figure 2 DISC CLOSED, Self-energized Seal

In figure 2, the disc and seat are engaged, and the process fluid is under low pressure. The spherical edge of the disc, with a larger diameter than the conical seat tongue, imparts a thrust of approximately 600 pounds per linear inch against the seat. The mechanical properties and shape of the metal seat allow it to both flex and maintain a constant thrust against the disc.

This controlled loading prevents the occurrence of bearing failure and reduces the leakage and wear between the components.

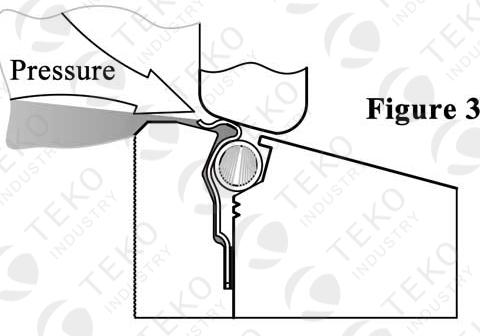

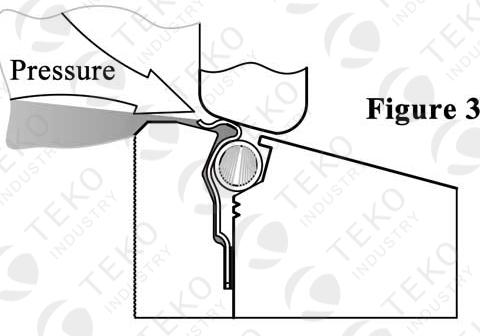

Figure 3 DISC CLOSED, Pressure-energized Seal (Seat Upstream)

As line pressure increased, the process fluid enters the sidewall area and applies a load against the parallel-spaced sidewall and convergent sidewall of the metal seat. The seat moves towards the downstream sidewall while being supported axially by the support ring, as shown in Figure 3. The cavity shape confines the seat movement and directs the movement radially inward towards the disc; the higher the line pressure, the tighter the line contact between the disc and seat. The metal seat, shaped by a special hydroforming process, is able to flex under these loads and return to its original shape after removal of the loads.

This dynamic seal, sealing equal to Flowseal, is totally unique among high performance butterfly valves.

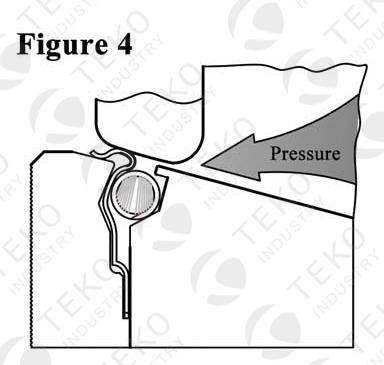

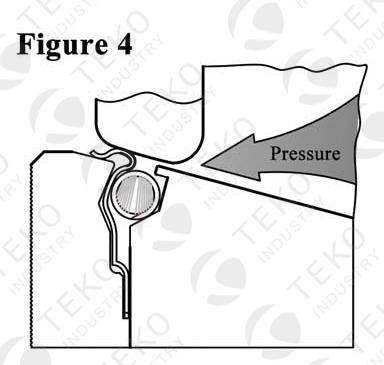

Figure 4 DISC CLOSED, Pressure-energized Seal (Seat Downstream)

The valve is bi-directional (in some instances, modifications may be required to operate his arrangement for dead end service). The cavity and seat sidewalls are symmetrically designed to permit, confine and direct movement of the seat to the disc to dynamically seal with line pressure in the seat downstream direction, as in Figure4. Recommended installation direction is “SUS”(seat upstream), as figure 3.

The stainless steel back-up ring interacts dynamically with the metal seat for axial support in seat sealing. Additionally, this ring effectively restricts corrosion ad particulate build-up in the cavity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!