Flange End Lever Operation Carbon Steel High Performance Butterfly Valve

TEKO High Performance Butterfly Valve designed by our engineer with benefits of Low Cost, light weight, quick action, maintenance free and low toque.

Product features

- wafer , Lug and flange available

- Heavy-duty disc with wide disc edge

- Corrosion-resistant, single-component thrust bearing/disc spacer

- Disc Internal stop

- Deep stuffing box for extended life

- Disc design reduces seat wear

- Positively retained stem

- Blow-out proof Stem for safe Operation

- Patented Seat Design

Applications

- High-pressure water, oil, steam, gas, and slurry applications

- Chemical and petrochemical processing

- Utilities

- Pulp and paper

- Oil and gas production

- Fuel handling systems

- Air conditioning and refrigeration

- Marine

Principle of Soft seated

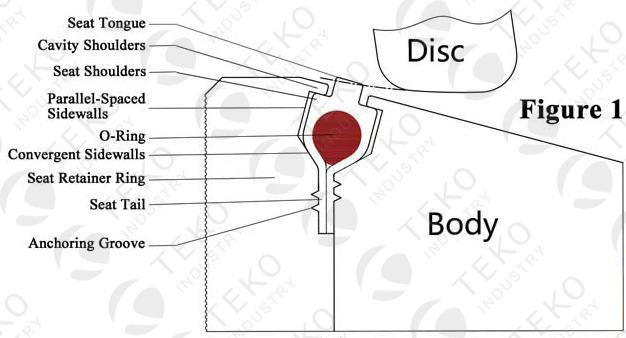

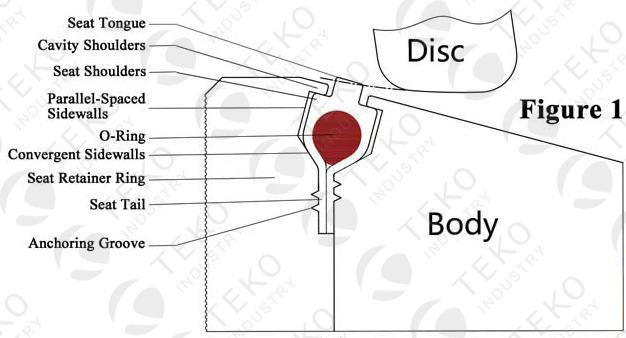

Figure 1 DISC OPEN

In Figure 1, the disc and seat are not engaged. In this position, the shoulders of the seat are forced against the cavity shoulders by the compression of the O-ring.

The seat is recessed inside the seat cavity and acts as a gasket I the anchoring groove area. The seat cavity is sealed from the exposure from the process fluid and protects the seat from abrasion and wear. The O-ring, which is completely encapsulated by the seat, is also isolated from exposure to the process fluid

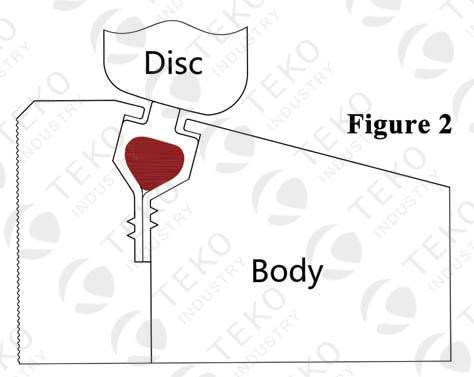

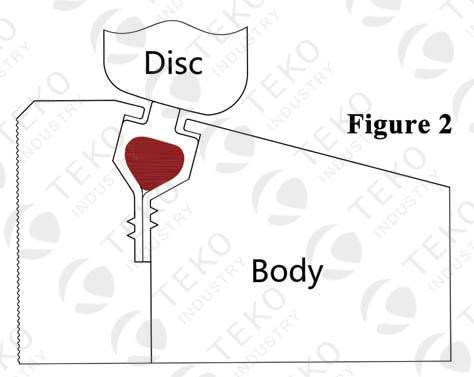

Figure 2 DISC CLOSED, Self-Energized Seal

In Figure2, the disc and seat are engaged, and the process fluid is under low pressure. The edge of the disc, with a larger diameter than the seat tongue, directs movement of the seat radially outward, causing the seat to compress against the convergent sidewalls of the cavity. The elastomeric O-ring imparts a mechanical pre-load between the discfand seat tongue as it is compressed and flattened by the disc; this is the self-energized mode for sealing at vacuum-to-60 psig.

As the seat moves radially outward, the seat shoulders move away from the cavity shoulders and open the cavity to the process media

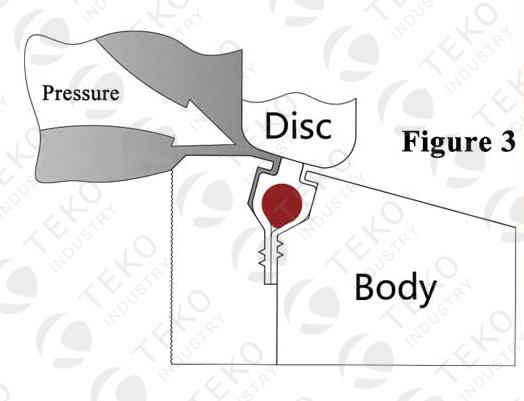

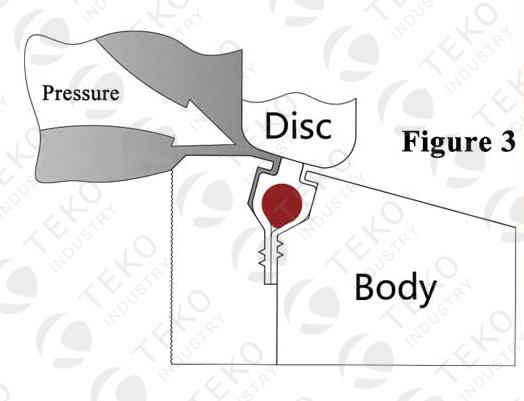

Figure 3 DISC CLOSED, Pressure-energized Seal (Seat Upstream)

As line pressure increases, the process fluid enters the sidewall area and applies a load against the parallel-spaced sidewall and convergent sidewall of the seat. The seat and cavity design permits the seat to move axially to the downstream sidewall, but confines the movement and directs the movement radially inward towards the disc; the higher the line pressure, the tighter the seal between the disc and seat. Because the O-ring is elastic, it is able to flex and deform under loads and return to original shape after removal of the load; it is the rubber which deforms, not the thermoplastic material

The dynamic seal s totally unique among high performance butterfly valves.

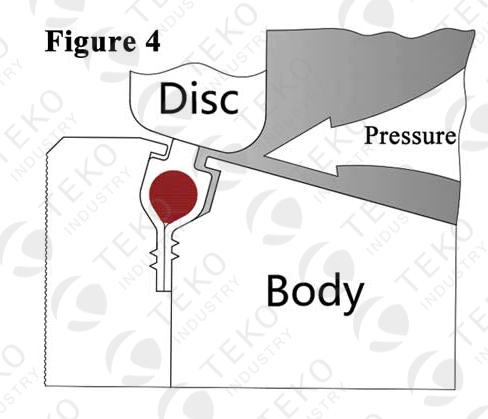

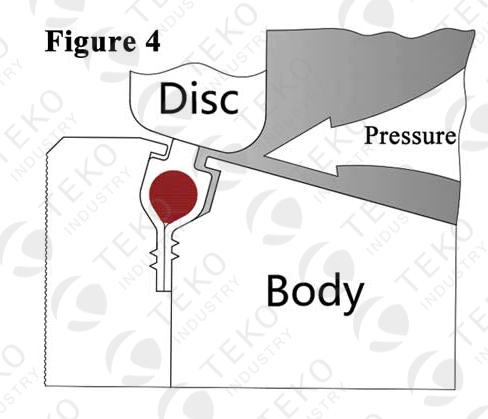

Figure 4 DISC CLOSED, Pressure-Energized Seal (Seat Downstream)

The HPBFV is bi-directional (in some instances, modifications may be required to operate this arrangement for dead end services). The cavity and seat sidewall are symmetrically designed to permit, confined and direct movement of the seat to the disc to dynamically seal with line pressure in the reverse direction. The disc edge is the segment of a sphere, and the seat is angled towards the disc edge to seal with pipeline pressure in either direction.

Recommended installation direction is “SUS”(seat upstream) , as in the Figure 3

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!