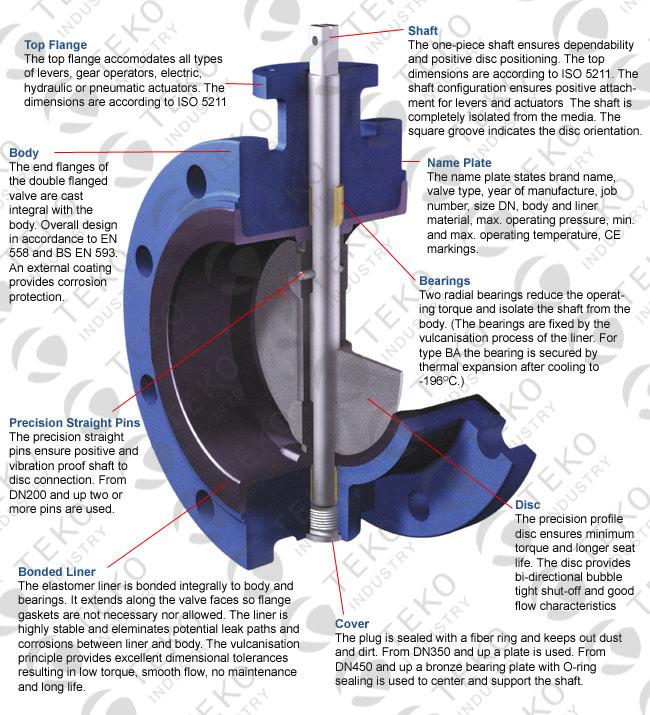

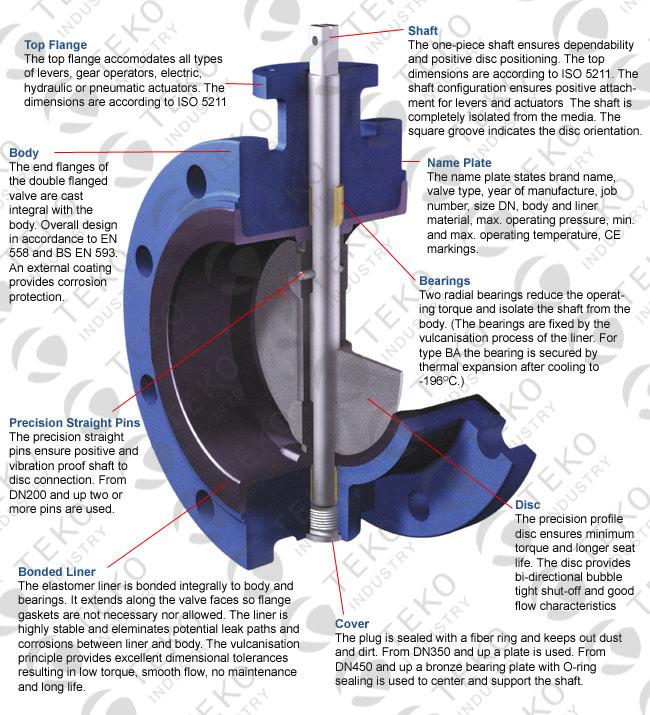

Worm Gear Operation Double Flange API609 Butterfly Valve With One Piece Through Stem

API609 Rubber Lining Hermetic Seal Double Flanged Butterfly Valve

Double Flange Type Butterfly Valve with Centric Disc and Bonded Liner. 100% bi-directional bubble tight shut off.

Applicable for all kinds of industries, especially shipbuilding, offshore, petrochemical, heavy industry, water treatment and civil engineering.

* Overall design generally in accordance to BS EN 593

* Face to face dimension in accordance to EN 558 table I, Series 13 (Except DN2000 and above)

* Top flange and shaft end in accordance to ISO 5211

* Working pressure from 0.1 Bar absolute up to 16 Bar (Test Pressure 17.6 Bar)

* Working pressure up to 25 Bar (Test Pressure 27.5 Bar) on request

* Suitable as end of line service valve

* DN50 – DN2200

* Mounting between flanges to DIN PN10, DIN PN16 or ASME Class 150

* Other type of connection on request

Seat Material Selection

Below is a general guide for seat material selection. When selecting seats, always consult the pressure / temperature charts and corrosion resistant guide or contact us for engineering help.

EPDM

Rated for temperatures -30°F to 250°F. EPDM is an abbreviation of a compound called Ethylene Propylene Diene Monomer. It is also commonly called EPT, Nordel, and EPR. EPDM is used extensively in the HVAC industry due to its resistance to polar compounds such as water, phosphate, esters, ketones, alcohols, and glycols. The EPDM material is also applicable for handling concentrated sulfuric acid, 20% sodium hypochlorite (bleach), chlorinated water for swimming pools, and other alkaline solutions. EPDM is not resistant to hydrocarbon solvents and oils, chlorinated hydrocarbons, turpentine, or any other petroleum based oils.

BUNA-N

Rated for temperatures 0°F to 180°F. Buna-N is also commonly identified as NBR, NITRILE, or HYCAR. It is an excellent general-purpose elastomer suitable for use with air, water as well as most petroleum oils and greases, automotive gasolines (except those which have additives), alcohols and glycols, L-P gases, propane and butane, fuel oils and many other fluids. It also exhibits good abrasion resistance, and excellent resistance to compression set.

PTFE

Rated for temperatures -20°F to 300°F. The PTFE liner overlays EPDM which is bonded to a rigid phenolic ring on the outside seat perimeter. The PTFE extends over the seat faces and outsides flange seal diameter, completely covering the EPDM elastomer layer of the seat, which provides the resilience for sealing valve stems and the closed disc.

VITON

Rated for temperatures 0°F to 300°F. This material offers higher temperature resistance and outstanding chemical resistance. It is resistant to hydrocarbon products and mineral acids, both dilute and concentrated solutions. However, it is never to be used in steam applications and is relatively poor in water service.

Component design

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!